5 Predictions for AI in the Manufacturing Industry

Artificial intelligence (AI) has enabled a new surge of applications across industries like healthcare, insurance, logistics, and retail. But its impact has completely changed manufacturing as we knew it. Almost a decade after the first mention on Industry 4.0, use cases that once sounded fictional are now a part of our reality. From smart co-bots to predictive shopfloor maintenance to generative designing – everything is possible.

This popularity is driven by the fact that manufacturing is full of analytical data for machines to analyze. It is the perfect fit for AI/machine learning. While other industries have a certain degree of emotions or language involved with their input variables, manufacturing is all about raw numbers.

How big is AI in manufacturing?

According to a 2019 report, more than half of the European manufacturers (51%) are implementing AI solutions, with Japan (30%) and the US (28%) following in second and third. This is because of the popular use cases maintenance (29% of all AI implementations) and quality check (27%). AI is increasingly becoming more and more important in realizing goals like enhancing productivity through automation, decreasing waste and improving yield, increasing sustainability through real-time sensors, and reducing maintenance costs via autonomous control systems. In fact, it is also pivotal in helping agile manufacturers introduce new products, thereby upending existing relationships and value chains.

Also read: Accelerating your Healthcare & Life Sciences Application Testing Cycles

The Pandemic Fallout

There is incontrovertible proof that supply chain disruptions, shutdowns of manufacturing units, and decreased demand amidst lockdowns across many countries have meant that AI-linked growth has suffered. However, as with all dark clouds, there are the inevitable silver linings. Take, for example, the previous global jolts (or ‘Moments of Truth’), namely SARS (2003) or the economic downturn (2008-9). If one were to look up the top 20 biggest winners by growth rates for those adversarial times, most companies belong to insurance, e-commerce, energy, and heavy manufacturing domains.

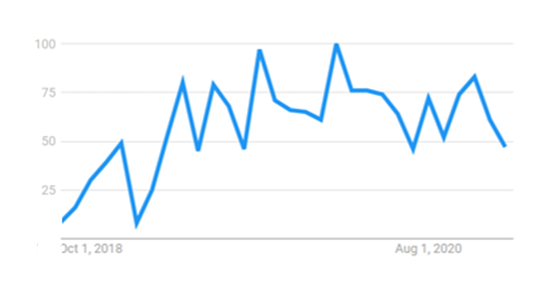

Source: Google Trends (x-axis: time, y-axis: number of searches)

On another note, search engines paint a promising future and market reports forecast a staggering growth of AI in manufacturing in the coming years! According to the BCG Henderson Institute report, during the four previous downturns, 14% of companies were actually able to increase both sales growth and profit margins. With the pandemic-driven digital transformation, AI has redefined itself in the manufacturing space with provisions to enable social distancing, near-real-time demand planning, and worker safety surveillance.

Here are five predictions for AI in the manufacturing industry.

Prediction I: Quality Assurance in manufacturing will move away from manual

‘Predictive Quality’ can reveal hidden causes of process-based production losses that manufacturers face today. Tomorrow’s AI solutions will include alerts and recommendations that inform teams and engineers of an imminent problem, and seamlessly shares preventive knowledge before faults actually happen. A brilliant real-life example of this is Shenzhen China Star Optoelectronics Technology Co., Ltd. (CSOT) which used AI to accelerate and automate product inspections to shorten production time and boost throughput while cutting costs. AI brought newfound speed and accuracy to product quality management. Another one of today’s use cases is the image processing algorithms that validate whether an item has been perfectly produced. By installing cameras at key points along the factory floor, sorting happens automatically and in real-time.

Also read: 3 Use cases of Image mining and Text mining in 2021

Prediction II: Manufacturing systems will shift from Redundancy to AI Resilience

Future manufacturing setups will favor increased use of ‘Digital Twins’ to enhance asset performance. Digital twins are currently used to improve product understanding by enabling businesses to collect data from their virtual twins. Since product permutations are available, customers are shifting their purchase decisions from design considerations to performance metrics. Additionally, manufacturers will benefit through AI-enabled logistics optimization that automates usage tracking and replenishment processes.

Prediction III: Manufacturing will evolve from marketing patterns to AI predictions

Post-COVID, shifting consumption patterns are surging demand for AI’s potential for predictions. As worldwide consumption patterns are severely altered, there is simply no ‘previous’ data to compare and contrast this new normal. This is dramatically impacting manufacture and fulfillment capacities. In the years ahead, AI’s game-changing applications (like AI control towers) will enable manufacturers of different goods and products to detect, optimize, and react in real-time to the new consumption patterns.

Prediction IV: Manufacturing ecosystems will graduate from Prototyping to Performance

Graduating from AI ‘prototypes’ to high ‘performing’ operations means manufacturers will scale their AI solutions across geographies/multiple factories. Consequently, there will be sizable investments in integrating legacy IT systems, creating new Industrial IoT systems, and setting up central data governance frameworks. Be it using deep learning for defects detection, or predicting energy consumption with machine learning, gathering accurate prototyping data to feed AI technologies is one step. High-performing manufacturing companies will go even further. They will create AI expertise pools in data sciences and data engineering to exploit this data avalanche and solve intractable business challenges.

Also read: 5 Essential Data Engineering Trends for 2021 and beyond.

Prediction V: Manufacturing leadership will bring Persistence to ‘Plus’

While major manufacturers are experimenting with AI use cases, scaled deployment is rare. Human-powered AI companies will gradually move beyond pilots and proofs-of-concept to scale. As AI prototypes begin to prove values and versatility, manufacturing companies will redesign technology and org. structures top-down. More often than not, leaders in the logistics, healthcare, finance, audits, and insurance industries will battle the “no-human” mindset to augment the ‘plus’ business model: ‘Human + AI’.

To sum up, in the coming future, there will be a rise of AI-powered companies that seamlessly combine AI with human judgment and experience. In fact, with increased AI adoption, we can soon expect #HumanFirstDigital to become the norm in manufacturing.