Control maintenance cost and unleash the true potential of critical assets

Enabling Smart Energy Management & Optimization for Modern Manufacturing

Apexon is a digital-first technology services firm specializing in accelerating business transformation and delivering human-centric digital experiences. For over 20 years, Apexon has been meeting customers wherever they are in the digital lifecycle and helping them outperform their competition through speed and innovation.

Our reputation is built on a comprehensive suite of engineering services, a dedication to solving our client’s toughest business and technology challenges, and a commitment to continuous improvement. We focus on three broad areas of digital services: Experience, Digital Engineering, and Data. Apexon also possesses deep expertise in Manufacturing.

Artificial Intelligence (AI) is increasingly employed by manufacturing companies and asset-intensive organizations today. The utilization of AI-driven APM (Asset Performance Management) aids in ensuring asset reliability while reducing the need for reactive repairs through predictive maintenance. Simultaneously, it facilitates the harnessing of the substantial volume of data generated by feedback mechanisms (sensors etc.) for real-time monitoring and reporting of critical assets.

As such, it becomes imperative to integrate a robust APM (Asset Performance Management) functionalities that harnesses AI algorithms to deliver favourable business outcomes.

5500+ Digital

Engineers

Headquartered

in Silicon Valley

25+ Accelerators

and Solutions

Backed by Goldman Sachs

and Everstone Capital

18+ Global

Delivery Centers

Additional Locations:

New York, Chicago,

London, Mexico and India

Apexon’s AI-powered, real-time (APM) Asset Performance Management accelerator is designed to enhance asset uptime and optimize overall efficiency:

Comprehensive KPI Visibility:

Gain real-time insights through continuous monitoring, ensuring a complete overview of key performance indicators (KPIs)

Integrated Dashboard:

Experience seamless monitoring with a centralized dashboard that provides a live feed of asset status and performance data.

AI-Driven Predictive Models:

Utilize embedded AI-based predictive models to proactively identify potential issues and gaps in asset performance, enabling timely preventive maintenance interventions.

Amazon CloudFront

AWS WAF

Amazon API Gateway

AWS Lambda

AWS Glue

Amazon Athena

Amazon Kinesis

AWS IAM

AWS KMS

Amazon SNS

Amazon Aurora

Amazon Redshift

Amazon CloudWatch

Amazon ElastiCache

AWS QuickSight

AWS cloud combined with digital transformation, consulting and business re-engineering services from Apexon can address the key challenges faced by the manufacturing industry, such as cost, poor monitoring, environmental compliance, and energy management and optimization.

The accelerator comes with three broad feature sets:

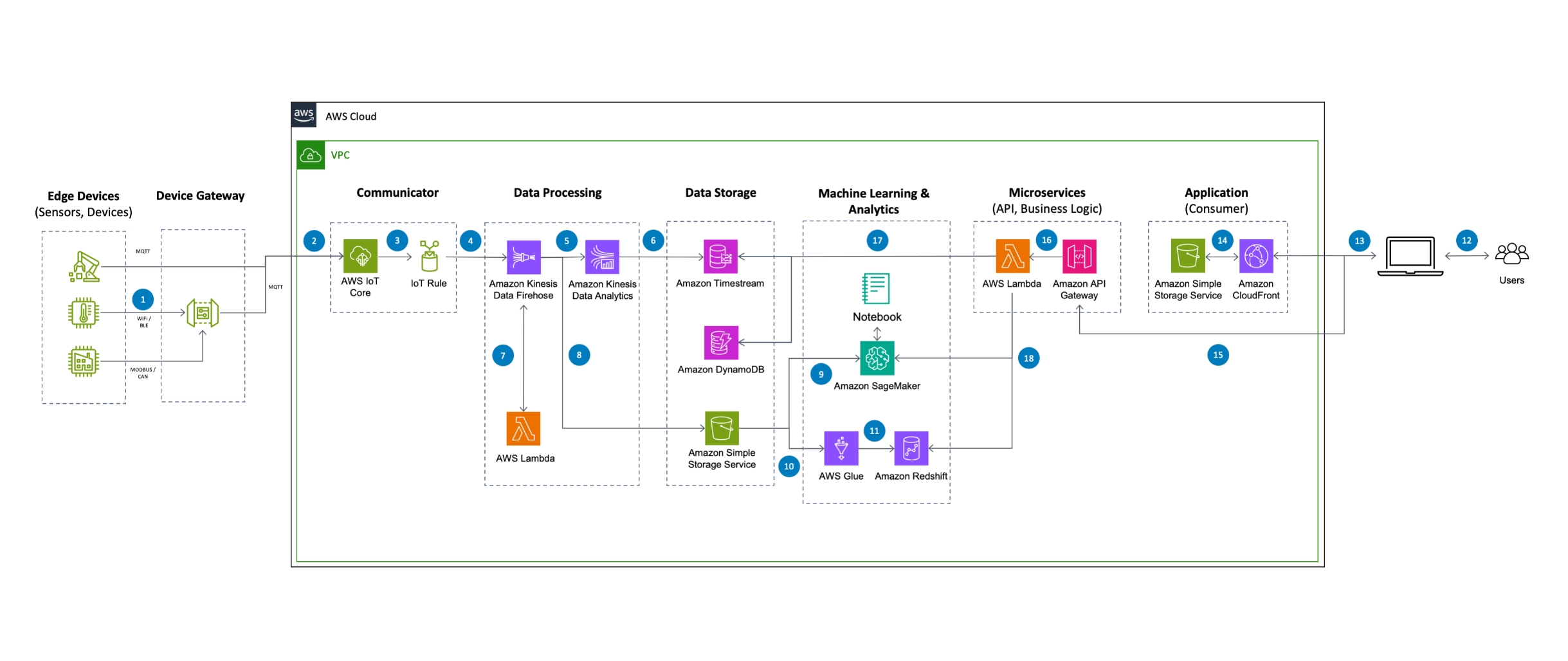

Collection of data from a variety of sources, including IoT (Internet of Things) devices, Edge devices, and companion applications. This comprehensive data gathering ensures that all relevant information is captured in real-time.

Customization of events and alerts, the organizations can tailor notifications to specific criteria, enabling them to monitor and analyze issues and potential failures promptly. These alerts help prevent costly downtime by addressing problems before they escalate.

Robust feature sets for monitoring and managing Key Performance Indicators (KPIs). These features provide organizations with valuable insights into their business performance, allowing for data-driven decisions to optimize operations continually.

Collection of data from a variety of sources, including IoT (Internet of Things) devices, Edge devices, and companion applications. This comprehensive data gathering ensures that all relevant information is captured in real-time.

Incorporating predictive analytics, offering insights into potential issues and maintenance needs. This proactive approach allows organizations to schedule preventive maintenance, reducing the risk of unexpected breakdowns and minimizing operational disruptions.

Enabling real-time monitoring and management across various dimensions, including assets, devices, applications, and support services. This comprehensive coverage ensures that organizations have full visibility into their operations, allowing for timely interventions and optimizations.

Cost Savings through Operational Excellence (OE)

By correlating asset performance data with overall operational excellence metrics, organizations can identify areas for cost reduction and process optimization. This alignment of asset performance with OE leads to cost savings, ultimately contributing to higher profitability.

Real-Time Tracking for Defect Management

Customizable, real-time dashboards and reports, simplifying the tracking of defects and performance issues. This real-time tracking capability enables organizations to swiftly respond to issues, reducing operational disruptions and associated costs. Higher customer trust and satisfaction result from a smoother, more reliable operation.

Preventive Maintenance and Abnormality Detection

AI models detect abnormalities in asset performance, this proactive approach allows organizations to prioritize preventive maintenance activities, avoiding costly unplanned outages. This not only reduces maintenance costs but also enhances overall asset reliability, contributing to cost savings and higher customer satisfaction.

Efficient Operations and Increased Productivity

Boost asset uptime and overall operational efficiency, by leveraging AI-driven insights. It helps organizations identify areas for improvement in their operations, leading to increased asset uptime, higher productivity, and ultimately, greater profits.

Partner with us to optimize your operations and reinvent supply chains, leveraging our proven methodologies and expertise.