Enabling Smart Energy Management & Optimization for Modern Manufacturing

Enabling Smart Energy Management & Optimization for Modern Manufacturing

Apexon is a digital-first technology services firm specializing in accelerating business transformation and delivering human-centric digital experiences. For over 20 years, Apexon has been meeting customers wherever they are in the digital lifecycle and helping them outperform their competition through speed and innovation.

Our reputation is built on a comprehensive suite of engineering services, a dedication to solving our client’s toughest technology problems, and a commitment to continuous improvement. We focus on three broad areas of digital services: Experience, Digital Engineering, and Data. Apexon also possesses deep expertise in Manufacturing.

Energy and resource management is playing an increasingly fundamental role for manufacturers. On one hand, increasing energy expenses are becoming noticeable in production costs, and on the other hand, profitable margins can only take effect if costs are reduced.

Effective energy management in manufacturing is essential to control costs and maintain productivity. Accurate data collection, preferably with IoT technology, is crucial for informed decision-making. Meeting government energy efficiency standards is often necessary for accessing benefits like tax incentives, but it can be challenging without the right tools.

5500+ Digital

Engineers

Headquartered

in Silicon Valley

25+ Accelerators

and Solutions

Backed by Goldman Sachs

and Everstone Capital

18+ Global

Delivery Centers

Additional Locations:

New York, Chicago,

London, Mexico and India

Apexon’s NOC is an AI-based immersive accelerator to collect, analyze, visualize and react to insights in near real time to proactively optimize loads, reduce downtime and streamline efficiency. Our accelerator can play a key role in today’s dynamic energy landscape, where disruptions in energy availability and fluctuating prices are common challenges.

Real-time monitoring to minimize potential energy-related disruptions.

An integrated dashboard offering a live feed of your energy assets.

AI-based embedded predictive models to identify gaps and enable preventive maintenance.

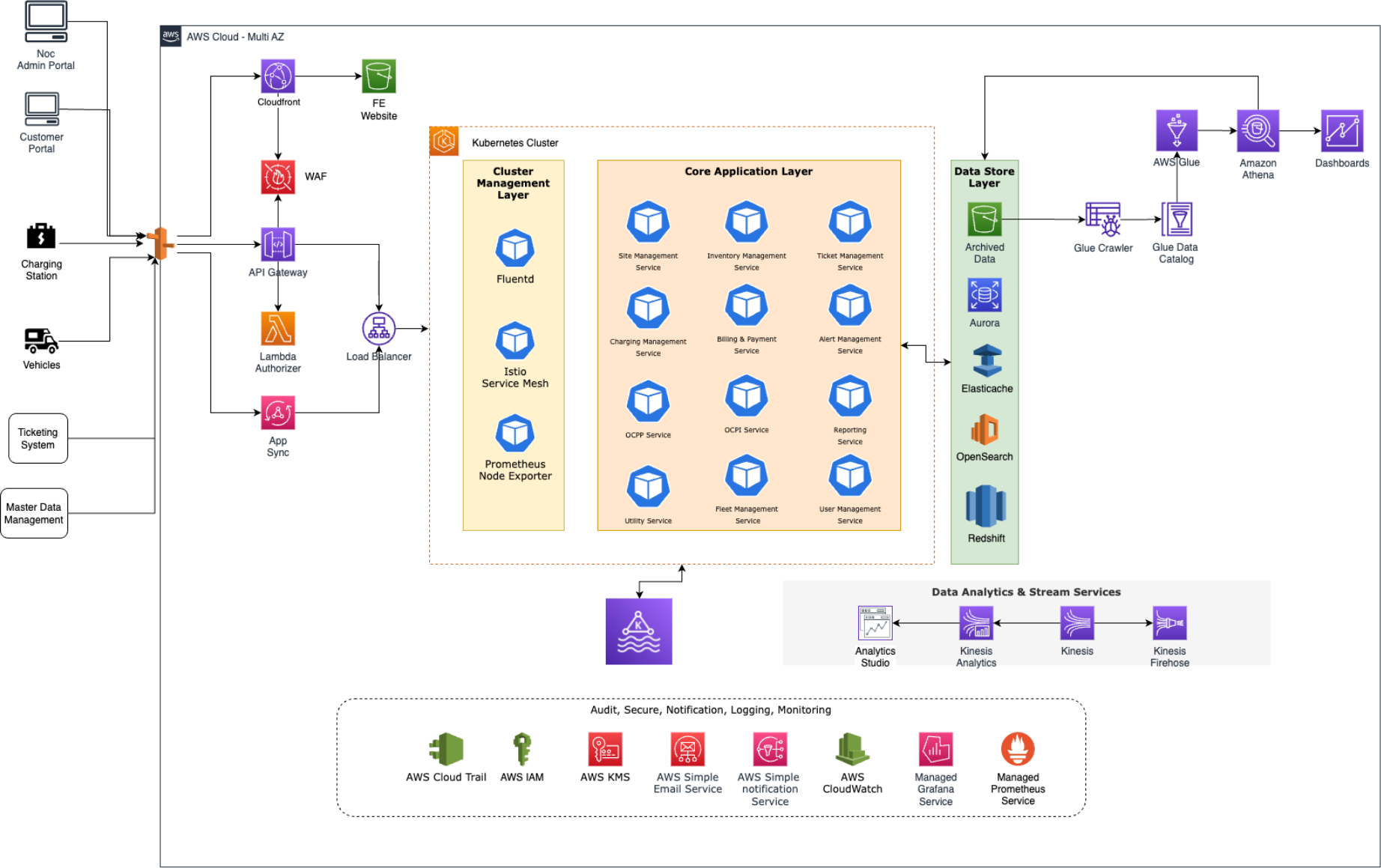

Amazon CloudFront

AWS WAF

Amazon API Gateway

AWS Lambda

AWS Glue

Amazon Athena

Amazon Kinesis

AWS IAM

AWS KMS

Amazon SNS

Amazon Aurora

Amazon Redshift

Amazon CloudWatch

Amazon ElastiCache

AWS QuickSight

AWS cloud combined with digital transformation, consulting and business re-engineering services from Apexon can address the key challenges faced by the manufacturing industry, such as cost, poor monitoring, environmental compliance, and energy management and optimization.

The accelerator comes with three broad feature sets:

It enables energy management within manufacturing operations through IoT connectivity. This connects devices, appliances, and energy sources in factories, providing real-time data for preventive maintenance, security alerts, remote monitoring, metrics tracking, and grid load management.

It collects data from various sources like sensors, smart meters, and third-party systems. This data is processed to reveal energy consumption patterns, inefficiencies, and optimization opportunities. Real-time processing allows for dynamic energy adjustments.providing real-time data for preventive maintenance, security alerts, remote monitoring, metrics tracking, and grid load management.

It collects data from various sources like sensors, smart meters, and third-party systems. This data is processed to reveal energy consumption patterns, inefficiencies, and optimization opportunities. Real-time processing allows for dynamic energy adjustments.providing real-time data for preventive maintenance, security alerts, remote monitoring, metrics tracking, and grid load management.

Cost

Our accelerator helps you correlate energy costs at the machine/equipment,production line, and plant level. By doing so, you can effectively avoid energy demand and supply risks, mitigate price peaks, and eliminate costly penalty charges.

Real-time Tracking

Customizable, real-time dashboards and reports, simplifying the tracking of defects and performance issues. This real-time tracking capability enables organizations to swiftly respond to issues, reducing operational disruptions and associated costs. Higher customer trust and satisfaction result from a smoother, more reliable operation.

Preventive

Our AI models are engineered to identify abnormalities and prioritize actions before they become critical issues. We also offer automated optimization of production schedules against energy costs, allowing you to strike a balance between productivity and resource efficiency.

Efficient Ops

Our accelerator is designed for rapid deployment, ensuring hat you can start realizing its benefits in no time. Additionally, real-time alerts with performance thresholds keep you informed, enabling proactive actions to maintain optimal operations.

Partner with us to optimize your operations and reinvent supply chains, leveraging our proven methodologies and expertise.